I recently built myself a new computer after using the last one for almost 5 years. My old computer was able to run all the programs I had without any real issues, but it was slowly getting more unstable over time, and the update to Windows 10 had been rough.

The Computer

This time I wanted to build a computer that could run the latest virtual reality headsets and I wanted to have something that again would last me quite a while. I typically buy the second fastest consumer CPU that is available as the fastest is normally at a high premium in cost but with little extra speed, but the Intel 6700K had finally come down to suggested retail price. I wanted the modern chipset that went with it so something on the Z170 chipset was what I looked for in a motherboard. My timing was not that great for a video card in that both NVIDIA and AMD were about to release their latest generation, so I actually waited over a month after buying the rest of my components before fully setting the computer up. The motherboard did have built in graphics and the CPU did as well, so I was able to test everything except for the new card.

I will make two observations. The first is that I have always felt it important to be agnostic about brands when making choices on most of the components. Years ago there was a great deal of variety in motherboards and how features were implemented on them. Today, the two main CPU makers (Intel and AMD) release a new chipset with each new CPU generation and that chipset is very full featured. I have almost always used Intel CPUs because for many years, they have been the best performing. AMD often wins on the cost to performance basis, but it has been quite a while since they have had a chip that can compete for pure performance. I did build an AMD-based computer a few computers ago because that generation they did have the best CPU.

CPUs are fairly quiet, but there often are techie “holy wars’ over video cards. I admit to have fought a little in them back when 3DFX and their voodoo chips revolutionized 3D, but I got over it. Now I just buy the card that I think does the best for me. The two main graphics processor unit (GPU) providers are NVIDIA and AMD (they bought ATI years ago). My last generation computer has an AMD video card (a 370) and that was based on AMD having better multi-monitor technology at the time as I like running 3 monitors. There are edge cases where AMD has had better chips, but for the most part, NVIDIA has had the highest performing chips for a while.

Unlike CPUs, the price jump to the most powerful GPU to the second best is still enormous and unless you really are a power gamer or power user, there is little need to get the best GPU. For the computer I just built, I ended up with an NVIDIA 1070 based video card (the board maker was MSI). I had considered the AMD RX 480 as it was a lot less expensive, but the demand was so high that cards were hard to find and the custom cards had not come out yet. So I went with the 1070.

I could write pages and pages on the latest and greatest differences between the board makers and the different CPU and GPU you could choose, but this blog entry will exist for a long time and tech sites are always much more current (I go to anandtech.com but ownership changes have made it less useful in the last year). So I will give some more general observations.

The premium priced components in the consumer space are all aimed at gamers. This tends to result in multi-color LED lights and a black (and usually red highlights) color scheme. There actually is very little value add from what I can tell from my research for the extra price you pay. There certainly is much less bang for the buck. The video card I bought is branded as an MSI “gaming” card and it looks nice but does not really offer any performance improvements over non-gaming cards.

Motherboards are similar. The Z170 chipset has plenty of solid boards that cost around $150 (can be found for less during sales). You can spend $250 to $300 and just get a few extra bells and whistles that you may never use.

One final comment, if you build the computer yourself, be prepared to troubleshoot yourself and to have to refresh your knowledge. I had a faulty power supply and it took me quite a while to track the problem down. Google and technology forums are your friends here.

This is the system I ended up putting together:

Intel Skylake Core i7-6700K

– the fastest CPU currently available. Depending on luck, can be overclocked a fair amount

Cooler Master Hyper 212 EVO – CPU Cooler with 120 mm PWM Fan

– One of the bestselling coolers. Quite tall, was interesting to install

ASUS Z710 – AR

– all of the modern features of the chipset and none of the “gamer” bells and whistles that jack up the price. PCI-e sharing (which is common for the chipset) so might be a concern for dual GPU use but I plan on only using one GPU.

GPU – MSI Gamer NVIDIA GTX 1070. As I mentioned, both the main GPU companies just released new cards and it is hard to find cards priced at regular retail prices.

G.SKILL TridentZ Series 16GB (2 x 8GB) 288-Pin DDR4 SDRAM DDR4 3733 (PC4 29800)

– this is actually somewhat of a waste. Super-fast RAM that I probably would not need and I could of gone down a few notches in speed and double the amount for the same price as I will not heavily overclock

CM Storm Scout 2 Advanced – Gaming Mid Tower Computer Case with Carrying Handle and Windowed Side Panel – Black

– This is an updated version of the case I have been using the past 5 years. Roomy and has a handle on top which comes in handy more often than not. Plenty of room for fans, and a good front panel for USB

Antec 750 Gamer power supply. I originally had a corsair power supply but it was faulty.

– Should be way more power than I need, especially if I do not have 2 x GPU

SAMSUNG 950 PRO M.2 256GB PCI-Express 3.0 x4 NVMe Internal Solid State Drive (SSD)

– Very fast SSD (motherboard supported) that will be my boot drive and will have some applications on it

Mushkin Enhanced Reactor 2.5″ 256GB SATA III MLC Internal Solid State Drive (SSD)

– Secondary SSD for often accessed files and other applications

Seagate 3TB Desktop HDD SATA 6Gb/s 64MB Cache 3.5-Inch Internal Bare Drive

– Should be plenty of room, especially since I have a 16TB NAS

LG Black 16X BD-R 2X BD-RE 16X DVD+R 5X DVD-RAM 12X BD-ROM 4MB Cache SATA Blu-ray Burner

– I debated if I really needed an optical drive and finally decided to get one as I can see myself watching movies on the computer and I have a lot of Blueray disks (PS4 is my main player)

Razer BlackWidow Ultimate Stealth 2016 – Backlit Quiet Mechanical Gaming Keyboard with 10 Key Rollover

– Decided to try a mechanical keyboard. These have Razer designed mechanisms, not sure if as good as Cherry-MX switches. Quieter version.

Logitech G600MMO Gaming Mouse – Black

– Will move over from my existing computer. I do not use all the buttons and may look at another mouse

VR Headset

The latest technology that is just starting to go mainstream is Virtual Reality. There are two main contenders for the headset market right now – the Oculus Rift (which is backed by Facebook) and the HTC Vive which has teamed up with Steam (owned by a company called Valve and the main marketplace to buy PC games online).

If I had to sum up the main differences between the two headsets, I would say that the HTC Vive comes with two controllers and can be used standing and moving (called room-scale) and sitting down while the Oculus Rift is mainly meant to be used sitting down and does not as of now come with VR controllers. The Vive has a lot more content available for it now, but many programs are made for both headsets and there are not many non-game programs available.

I got to try out the Vive at uploadvr.com ‘ s offices in San Francisco when I was there for a meeting with a McGill University representative who wanted me to help in their entrepreneur program. I had read that the room-scale made a big difference and when I tried it out I agreed.

The experience in both headsets is pretty good and you do really get a sense of immersion far beyond what looking at a screen will give you. The Oculus Rift is about $600 and the HTC Vive is about $800, but the Vive comes with two controllers and two sensor boxes that enable the room scale VR.

I picked the HTC Vive as it has more software available today and because the built in ability to move around instead of just sitting down sold me on the system. The actual graphics capability is about the same between the two controllers and both are just emerging, so the “best” choice may change rapidly.

I have only used the headset for a few days., so I will hold off on a detailed review, but I can tell you that the base experience lives up to the hype.

I am waiting to see what non-game uses there are for the headsets. There is a fair bit of work being done to develop approaches and applications for the virtual world the headsets put you into that make it useful for non-games, but there are not that many real life examples yet. I will be attending a meeting on that topic in a few weeks and will update and right a new blog after I have more information.

Getting the headset to work was somewhat of a struggle and the programs are all new and very much “early access”, so I hesitate to recommend it for everyone, but it has been quite fun so far. One of my friends brought his young son over (son is around 10 years old) and the son was fascinated with the headset and wore it for hours.

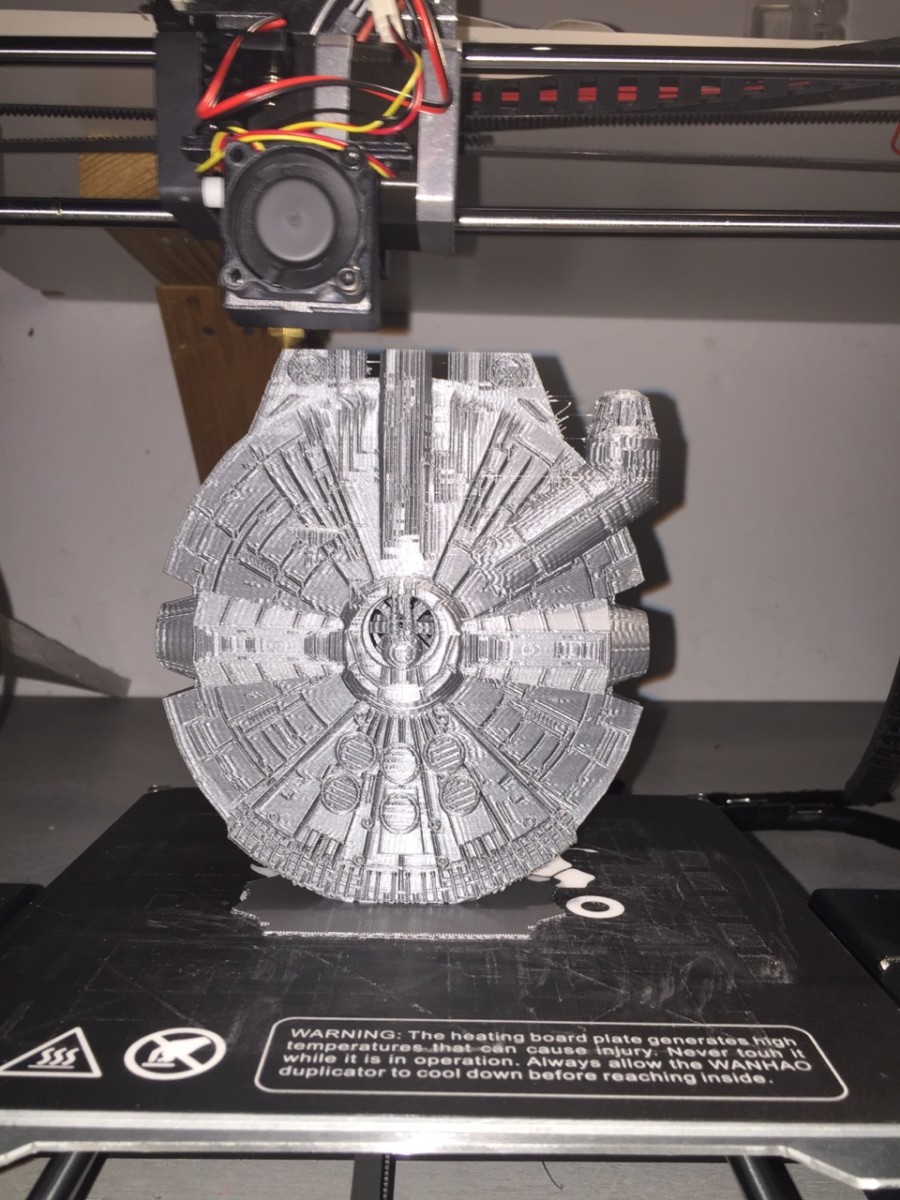

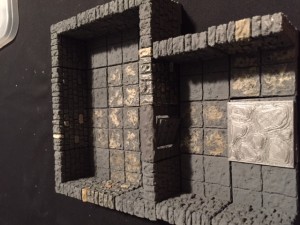

3D Printing

As I mentioned in an earlier blog, 3D Printers are technology that is still not quite ready for mainstream use. They still take a lot of fiddling with to get to work well and consistently and you need to be comfortable with at least some light mechanical work. I recently bought another 3D printer, the Wanhao Duplicator 6. It is over twice the price of the Wanhao Duplicator i3 I started with (and that is an excellent starter machine), but it is much more capable as well. I will do an update just on the new printer and what I have learned since I bought my first one. This update will include using a raspberry pi mini-computer to remotely control and monitor the printer.

The raspberry pi mini-computer part of my coming update will be extensive as well. Quite remarkable what you get for around $50.

Why Bother?

This is a blog on being a CFO and I usually have Tuesdays are purer “CFO” topics and Thursdays are where my occasional other blogs show up. So you may be wondering why I am writing on building a PC or VR headsets or 3D printers.

My reasons are quite simple – career growth and personal growth. I live in the Silicon Valley area and there is a lot of interest in the technology around computers, VR and 3D Printers. More and more, companies are looking for CFOs that are more than just the accounting and numbers person. IF I don’t expand my mind and learn by doing in areas like this, then how can I be credible when I claim to be a good fit for a technology company CFO role?

I get personal satisfaction on learning new things, but with the competition out there today, I really think that you need to keep actively learning. If you stop and rest on your laurels, you will be passed by. I often have had staff ask me how I got to know our company’s products, and it is the same drive that makes me want to understand VR Headsets that made me dig into how electricity comes from a solar panel.

So try not to dismiss other people trying to learn and very importantly, encourage your staff to do so.